Have you been looking for an alternative to building jigs with your welding projects? In tackling welding projects, creating your own jigs is a common approach to ensure precision and repeatability. However, this isn’t the only method available to maintain consistency and accuracy in your work. Off-the-shelf clamping systems, magnetic squares, and other pre-fabricated welding aids can serve as efficient substitutes. These ready-made solutions offer the advantage of saving time, as they eliminate the need to construct custom jigs for each new project.

The choice of an alternative to building your own welding jigs largely depends on the scope and frequency of your welding tasks. If you’re a DIY enthusiast who occasionally undertakes welding projects, investing in versatile, adjustable clamps might be more cost-effective and convenient. For more frequent welding work, you might consider a modular fixturing system that allows for a wide array of configurations. This ensures that you’ll have the necessary support for a variety of projects without the need for bespoke jigs.

If you’re a professional welder, the time saving from using clamps and fixtures is a massive cost saving. We have customers who have tripled their productivity due to no longer needing to build custom jigs.

Your tool selection, therefore, should be informed by the types of welding projects you typically engage in. Tools that offer adjustability and multi-functionality will not only reduce the need for custom-built jigs but also add efficiency to your workflow.

Alternative to Building Jigs for Welding Projects

Welding projects can be easily done without jigs by using various clamps, and blocks, mastering tack welding techniques, and using precise measurements and cuts.

Using Clamps and Other Alternatives

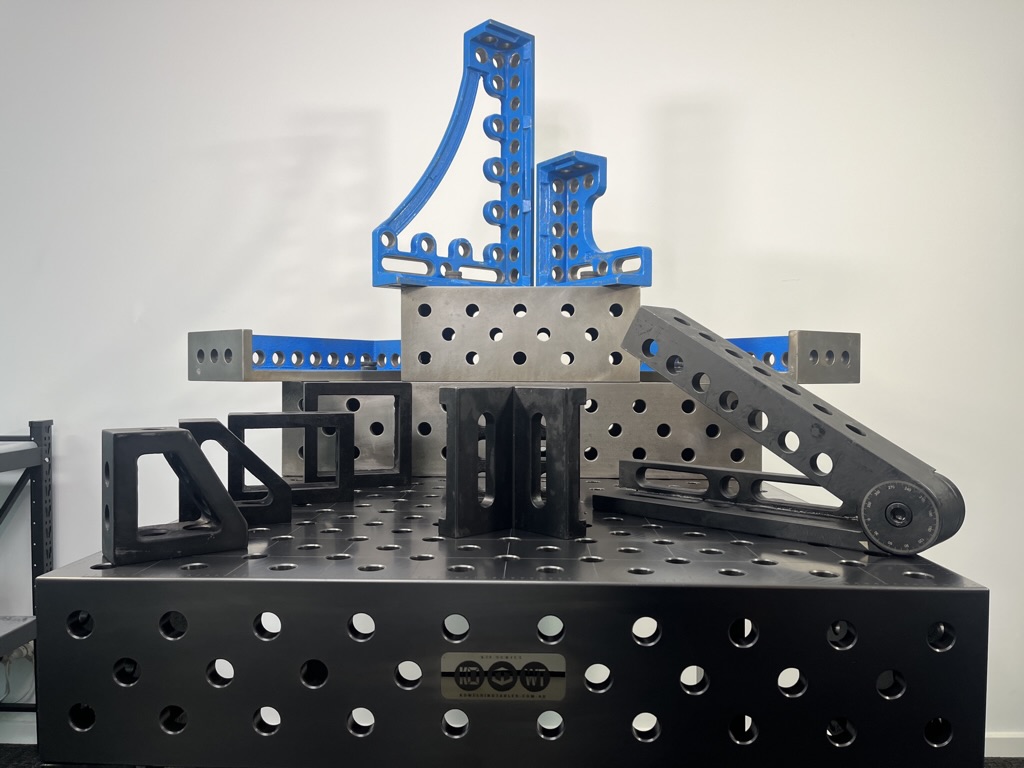

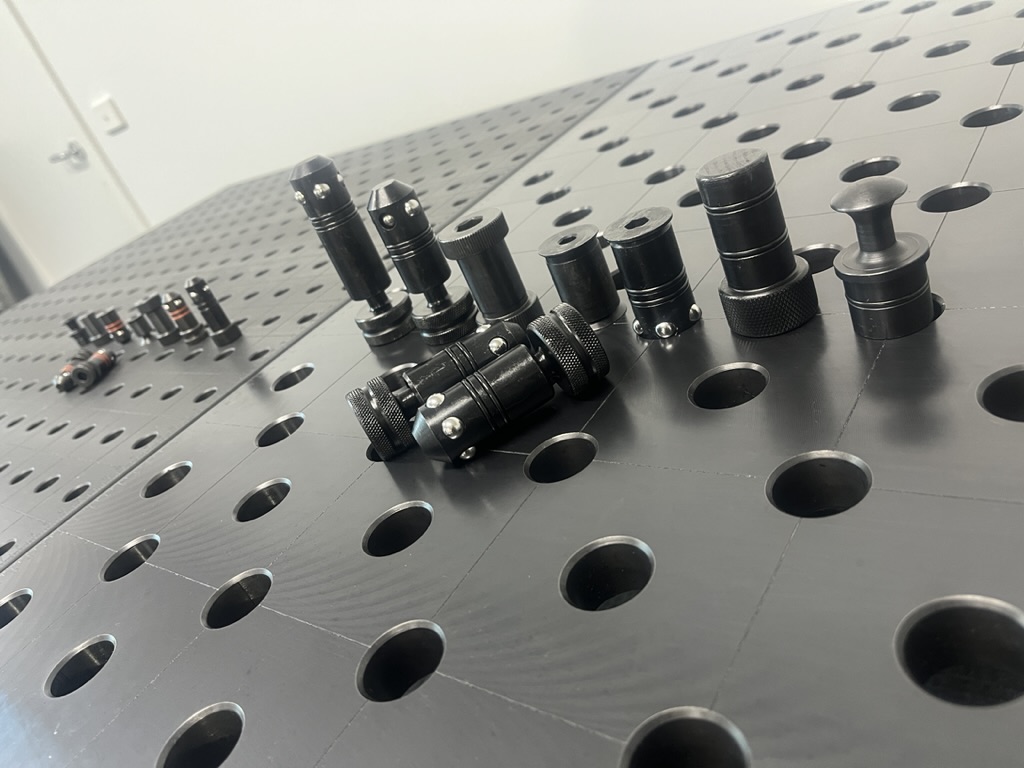

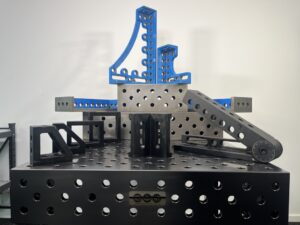

When you’re starting a fabrication project, clamps are indispensable for holding metal pieces securely. K28 clamps and K16 clamps are robust options for a range of applications, from small to large-scale projects. Proper use of clamps can substitute for the stabilisation that jigs usually provide. Ensure you have a diverse set, from handle clamps to toggle clamps, to accommodate different shapes and sizes of work pieces.

A good range of clamps coupled with pins, blocks, angles and stops will allow you a huge amount of flexibility in your clamping set-up. You will be able to tackle almost any job with this set-up.

Guidelines for Tack Welding

Tack welding is vital for aligning and holding your metal pieces together before final welding. Apply multiple small tacks at the beginning, middle, and end of your workpieces to maintain alignment without a jig. Remember, too many or too few tack welds can lead to distortions or weak joints. Striking a balance is key to the structural integrity of your project.

Measuring and Cutting Metal

Accurate measuring and cutting form the foundation of any successful weld project. You must measure twice and cut once to ensure the components fit together flawlessly, especially in the absence of jigs. Utilise our blocks and pins as guides, and apply techniques such as scribing to mark precise cutting lines. Always use sharp, appropriate cutting tools for the type of metal you’re working with to prevent material waste and ensure smooth edges for welding.

Frequently Asked Questions

Born and raised in Ocean Grove, Victoria, I’ve always loved working with my hands. During High School, welding became my passion. For over a decade, I’ve been at the heart of the welding industry, mastering techniques from structural steel to custom fabrication. My expertise led to the creation of “KO Welding Supplies” in 2018, a trusted supplier for welders and fabricators across Australia and New Zealand.

Recognising the need for a superior welding table, in 2021 I innovatively tested and launched the KO Welding table. Its precision and adaptability surpassed anything I’d used before. Drawing from extensive feedback, we realised one-size-fits-all wouldn’t work. Thus, koweldingtables.com.au was born, offering customisable, top-quality welding tables with transparent pricing.

Today, we’re reshaping the fabricator’s experience, one tailored solution at a time. You can read more about my experience here.