WELDING TABLES AUSTRALIA

Customisable Welding Tables by

KO Welding Tables® (KO | WT)

Welcome to KO | WT

Questions? (03) 7020 0234

CUSTOMER REVIEWS

Alex from KO was more than helpful with our orders, going the extra step to work with us on tailoring custom packages for our companies requirements.

The quality of the hardened tables is also impressive, my tooling from my other branded tables also fits.

Ill be ordering again in the future.

I found KO Welding and looked at their system in their Ballarat showroom. Awesome. They cost a bit but are very competitive in the market for a premium table. I made my own legs but the KO version is good. What a great thing to be able to make things square and flat instead of being on the concrete floor!

A great addition to my shed. All my visitors remark on the quality and functionality of it even if that’s not what they are there for… well done Alex and the team. Alex is responsive and accommodating before during and after the sale.

And for the products, they speak for them selves.

Been a customer from the start!

I purchased a size 9 Fleckz torch and the MEGA ceramic cup kit from KO Welding and they are a freaking fantastic combination. From the moment I put down some shiny tacks, I knew this was a step change.

This kit did the trick and put an end to weeks of frustration. Rainbow coloured welds have become the thing now.

Absolutely stoked!!

Five star welding tables…..

Definitely recommend this business.

I strongly urge anybody looking to buy a weld table to give Alex a call and get yourself one, best business decision.

Dealing with KO Welding was a seamless process. Alex was upfront and transparent about all aspects of the transaction, maintaining good communication from the initial enquiry, through fabrication, shipping, and even post-delivery.

Thanks to the team at KO Welding Tables from BG Custom Fabrication.

Gone are the days of welding up jigs for production orders, only then to cut them up and scrap the material when finished. This table allows us an infinite number of jigging possibilities that are cleaner, faster and loads more accurate.

Big Al at KO always goes above and beyond to ensure total satisfaction. Can’t recommend highly enough.

Keep up the good work!!

James @ ARC MAN WELDING

highly recommend

KO | WT fab benches are trusted by numerous Australian companies, institutions and individuals including:

PRICING LINKS - INSTANT QUOTE

K16 PRICING LINKS

K28 PRICING LINKS

THE KO | WT CUSTOM ORDER PROCESS

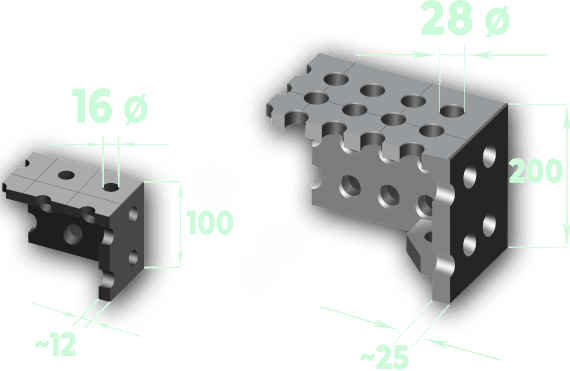

K16 OR K28?

BENEFITS

K16 BENEFITS:

Lighter – tables/clamps/fixtures are about half the weight of our K28 variant.

Hole distance – the standard hole grid is half the distance of our K28 variant.

Price – K16 table tops are more cost effective (fixtures are slightly more expensive, due to being less common/more intricate over the K28).

K28 BENEFITS:

Durability – will even more so, stand through the test of time.

Clamping power – increased clamping power by 50%.

Heat Dispersion – due to the thicker plate material the K28 table acts as a heat sink.

Load capacity – 1 tonne / 1㎡ (double of K16).

Fixture Tooling – larger range, more robust and more cost effective in price.

Note: We now have a 50mm grid pattern option for the K28.

Questions?

(03) 7020 0234 | sales@koweldingtables.com.au

LEARN MORE

Our First AMW Expo – What a Blast!

A few weeks ago, the KO Welding Tables® team hit the road and set up shop at the Australian Manufacturing Week (AMW) Expo in Melbourne

Why KO Welding Tables® Should Be Your First Choice for Welding Tables

When it comes to welding, precision, durability, and efficiency are everything. Whether you’re a professional welder or a passionate hobbyist, the right tools can make

Welding Table Height – What Height Do I Need?

How tall should my welding table be? What size legs should I get with my welding table? We get a lot of questions like these

K16 OR K28?

CONCLUSION

Our K28 is for those completing medium to heavy duty fabrication applications; from 2mm wall thickness tube to structural bridge cranes and everywhere in between. The 28’s can take a fair beating and will stay true flat for even further decades. Also due to the plate thickness increase, the 28’s base acts as a heat sink, allowing your work pieces to cool faster. You can of course complete light duty jobs with the 28’s, but if you’re solely completing light work go for the K16.

Questions?

Call us (03) 7020 0234

From the owners of kowelding.com.au

(KO Welding Supplies)

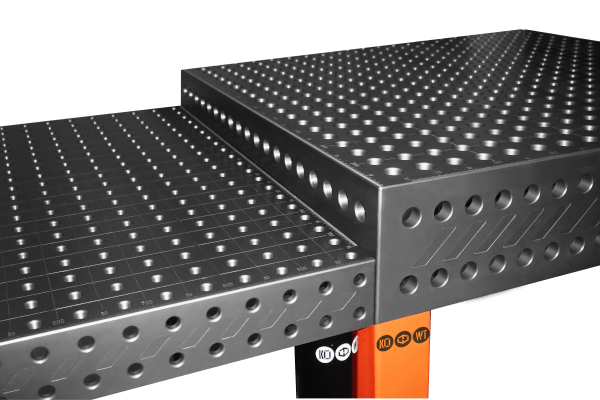

We are Australian owned and operated – Direct importers of: MODULAR | PRECISE | INDUSTRIAL | FABRICATION/WELDING BENCHES & ACCESSORIES.

TOLERANCES

Flatness: ±0.1mm (1m²)

Hole Distance: ±0.05mm

Hole Diameter: +0.05mm

Tolerances apply to all KO | WT tables and fixtures at the time of receiving goods. After many years of hard use, they may vary.