Description

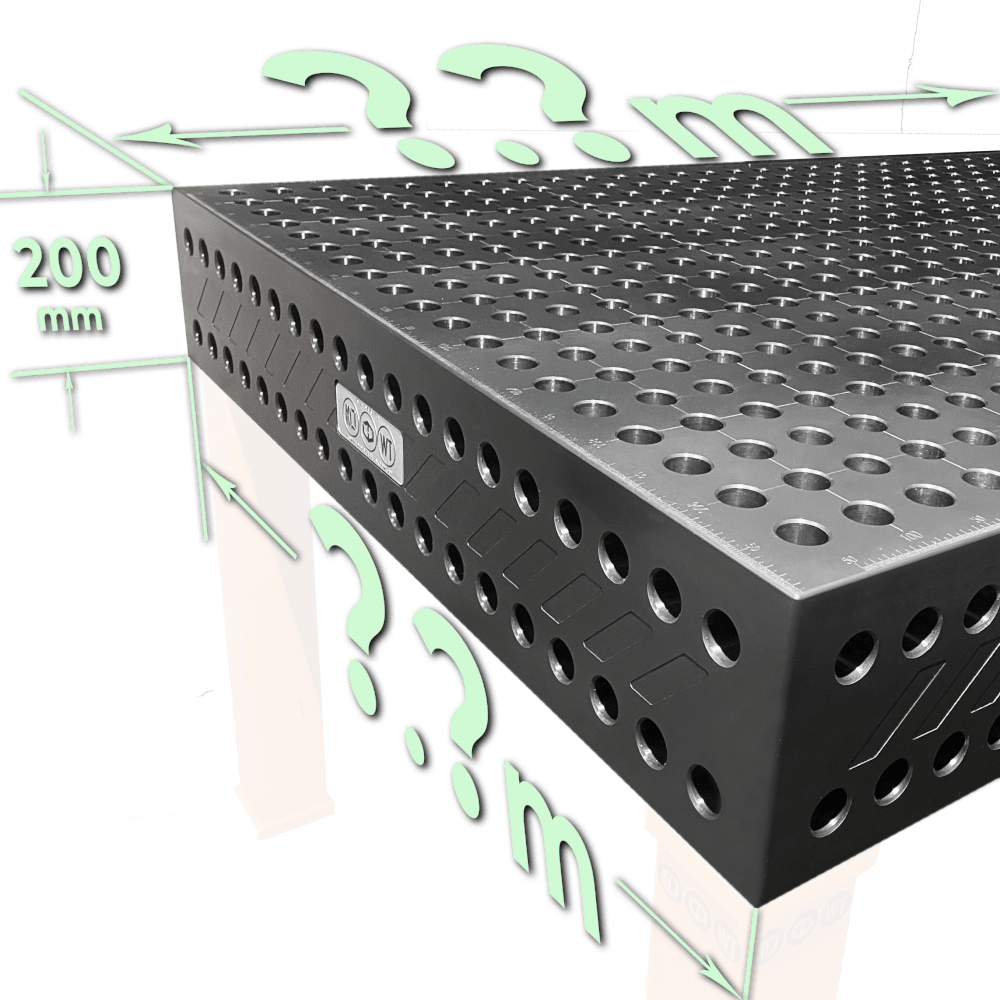

Choose your custom size: In 100mm increments – between 0.5m x 1.0m all the way up to 3.0m x 1.6m!

MATERIAL: CAST or STEEL?

1) T300 – CAST IRON

PROPERTIES: High quality sand resin cast, more superior than vacuum cast. Naturally spatter resistant, rougher and a slightly tougher surface. Greater heat dispersion and engraving lines are rougher (see picture below).

HARDNESS: Differs per treatments: Standard / Burnished ~240HV | Nitriding ~450HV.

DENSITY: 7.25 g/cm³.

TENSILE STRENGTH: 345 MPa.

COMPARE SURFACE OF MATERIALS:

2) S355 – STEEL

PROPERTIES: Smooth surface, increased hardness (especially with nitriding treatment),

cleaner ruler and grid etchings.

HARDNESS: Differs per treatments: Standard / Burnished ~250HV | Nitriding ~550HV.

DENSITY: 7.80 g/cm³.

TENSILE STRENGTH: 355 MPa.

TREATMENT: NONE or BURNISHED or NITRIDING?

1) NONE – No surface treatment, raw material (silver in colour).

BENEFITS: Shiny silver colour.

HARDNESS: Cast Iron ~230HV | Steel ~240HV.

2) BURNISHED – Oxidation treatment (black in colour).

BENEFITS: Rust resistant.

HARDNESS: Cast Iron ~230HV | Steel ~240HV.

3) PLASMA NITRIDING – Ion Nitriding Treatment (black in colour).

BENEFITS: Huge hardness increase, spatter resistant, heat dispersion, rust resistant.

HARDNESS: Cast Iron ~450HV | Steel ~550HV.

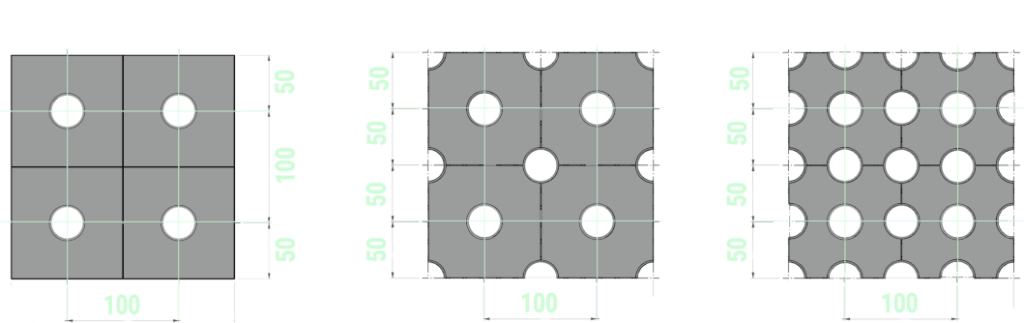

HOLE GRID: STANDARD or DIAGONAL or 50mm?

Standard, has a hole spacing of 100mm.

Diagonal, has an extra hole in the centre compared to the Standard.

50mm, has a whopping 9 holes per 100mm² – allowing for even more clamping and fixing possibilities!

TOLERANCES

HOLE DIAMETER: +0.05mm.

(03) 7020 0234 | sales@koweldingtables.com.au